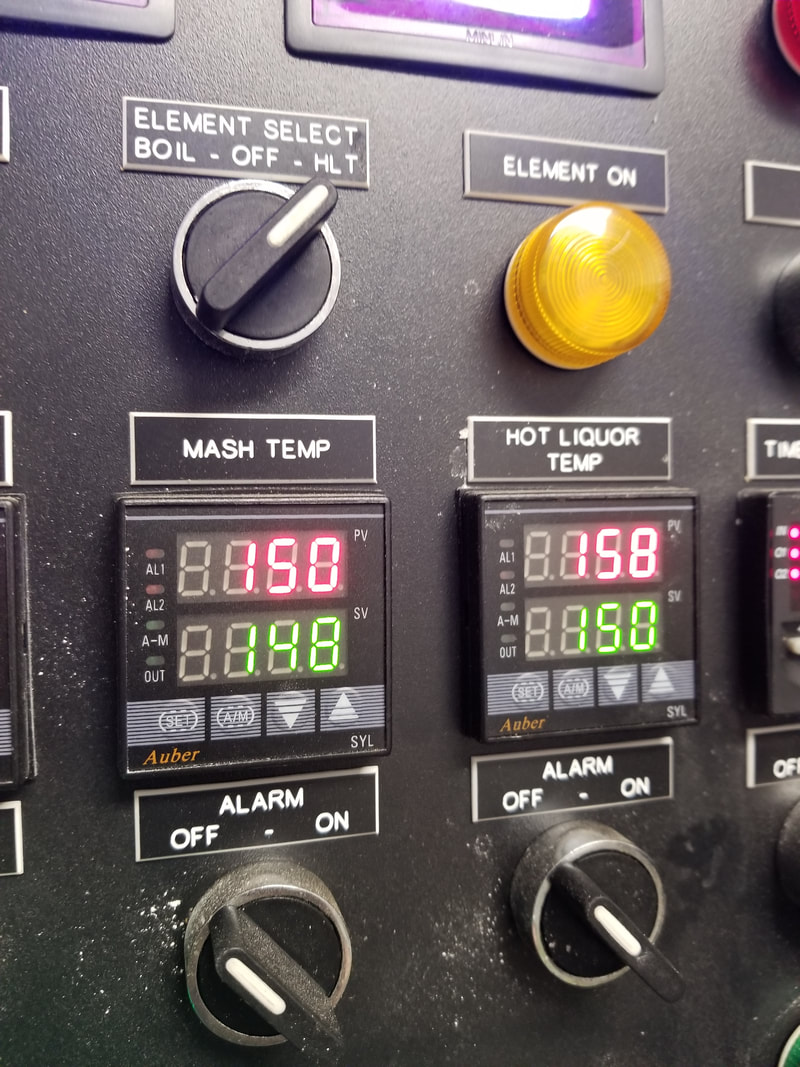

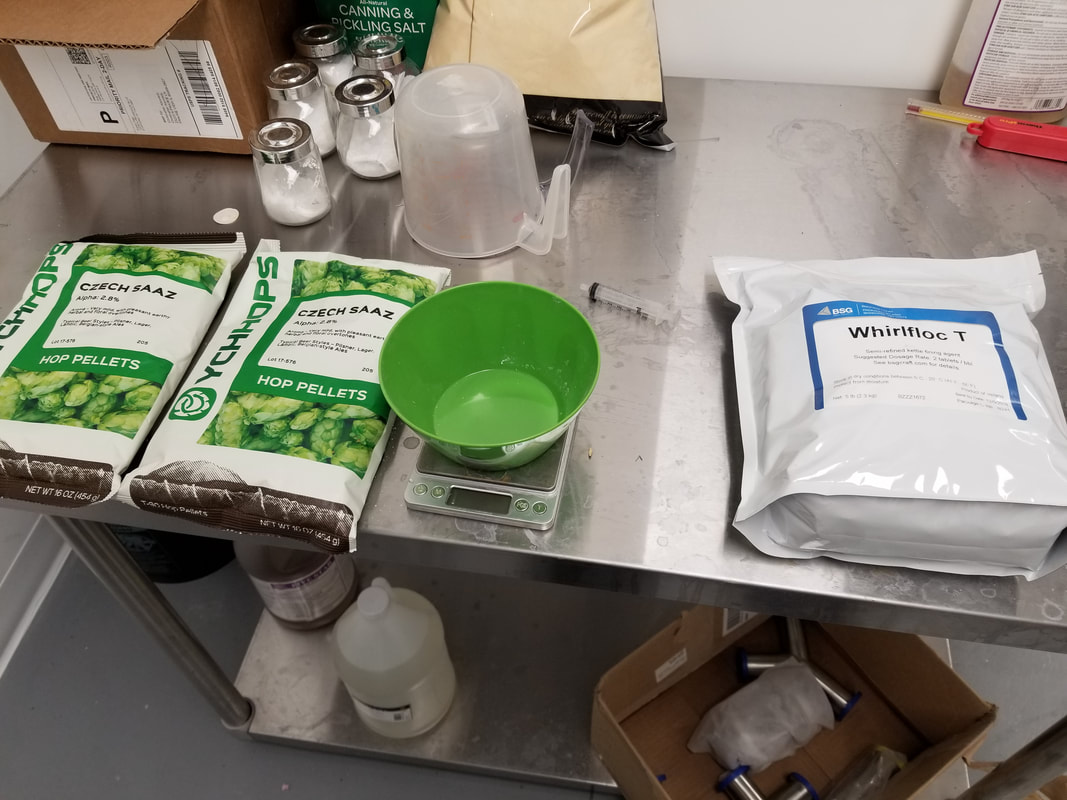

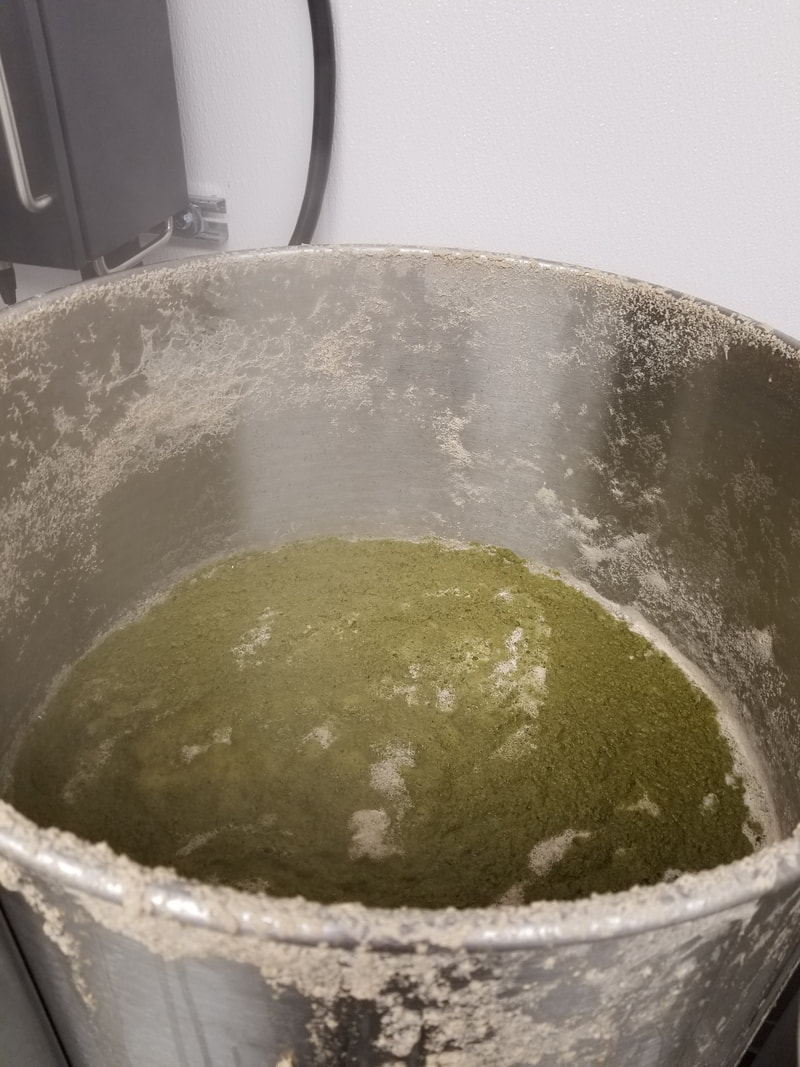

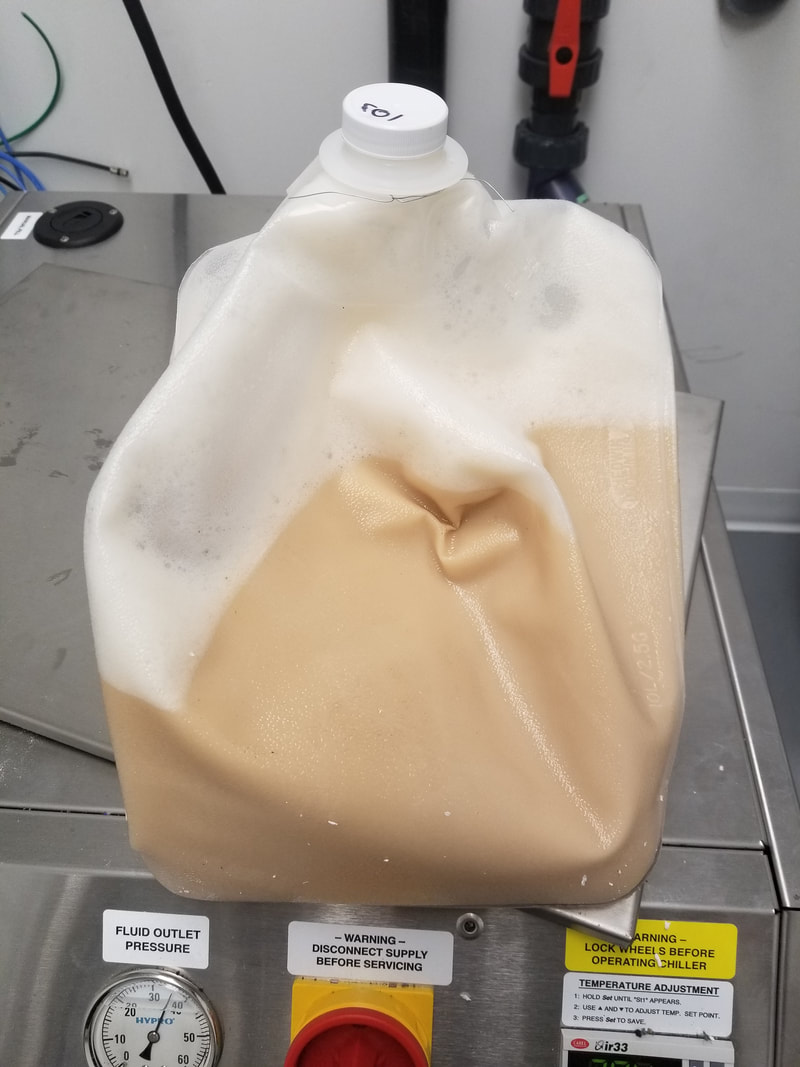

Brewing Days are Here Again!1/12/2019 When we decided to switch from home-brewers to commercial brewers, we had to take a little hiatus from brewing beer to get the business up and running so we have been frothing at the mouth to get back at it for about the last 6 months. In typical feast or famine mode, we went from no brewing, to brewing eight batches of four different beers this last week. Here are some pics from a typical brew day for us: First, we fill the HLT with about 105 gallons of water and get that heating to about 160 degrees. That takes a while so we do some prep work like milling grain. Each recipe is different, but each batch averages about 150 pounds of grain. Once we have the HLT at the temperature we want, we move about half the water over to the mash tun and stir in all the milled grain. Once all the grain is in, we use a recirculating system that draws water from under the grain, runs it through a coil in the HLT that remains heated at the proper temperature, and then back on top of the grain bed. Doing this at specific temperatures, soaks sugar off of the grain and turn our water into wort. After the mash, we fly sparge, which is the process of moving the wort from the mash tun to the boil kettle. This is the mash tun after it has been emptied of wort. The spent grain now has to be shoveled out and disposed of. We are looking for any farmers who want this spent grain as feed. Its free and we hate throwing it away! While we are waiting for the wort to boil, we prepare the hops and other additions. Depending on the recipe, different hops are added at different points in the boil. The Whirlfloc you see on the right is added with 15 minutes left in the boil to help with beer clarity. A rare sighting of our brewers, Chris and Chris. As the wort nears boil temperature, a film forms on top of the wort called the hot break. We skim it off as it helps with beer clarity and stability down the road. Boiling wort. It might not look very appealing in this state, but in about a month you guys are going to be loving it! While the wort is boiling, we have to sanitize our fermenter in preparation for the wort. We use a non-foaming, iodine based sanitizer in this situation and run a loop of it through a clean-in-place (CIP) spray ball at the top of the fermenter. By running the loop through a pump, we generate enough force to make sure all of the tank gets sanitized. If you noticed the buckets of grain in the foreground, those are waiting for our second batch of the day. Every day we brew, we brew twice in order to fill the fermenters. It makes for a long, but fun, day. Once the boil is done, it is time to move the wort into the fermenter. If you can follow the picture, the hose goes from the boil kettle to a pump. From the pump it goes through a heat exchanger (the square thing with blue hoses coming out of it) that takes the wort from 212 degrees down to about 60 degrees almost instantaneously, and then into the fermenter. On this particular day, we were brewing Prairie View Premium Lager and needed to get the wort down to about 50 degrees before pitching the yeast. Once the yeast are pitched, they begin eating the sugar in the wort, turning it into CO2 and alcohol. After about 12 hours of brewing, you'd think the day would be done, but there is a lot of cleaning to be done when the brew day ends. After an hour or two, the brewery is clean and ready for the next brew day.

AuthorCheck back often for updates on our events and our progress towards opening our commercial nanobrewery. Archives

January 2019

Categories |

Proudly powered by Weebly

RSS Feed

RSS Feed