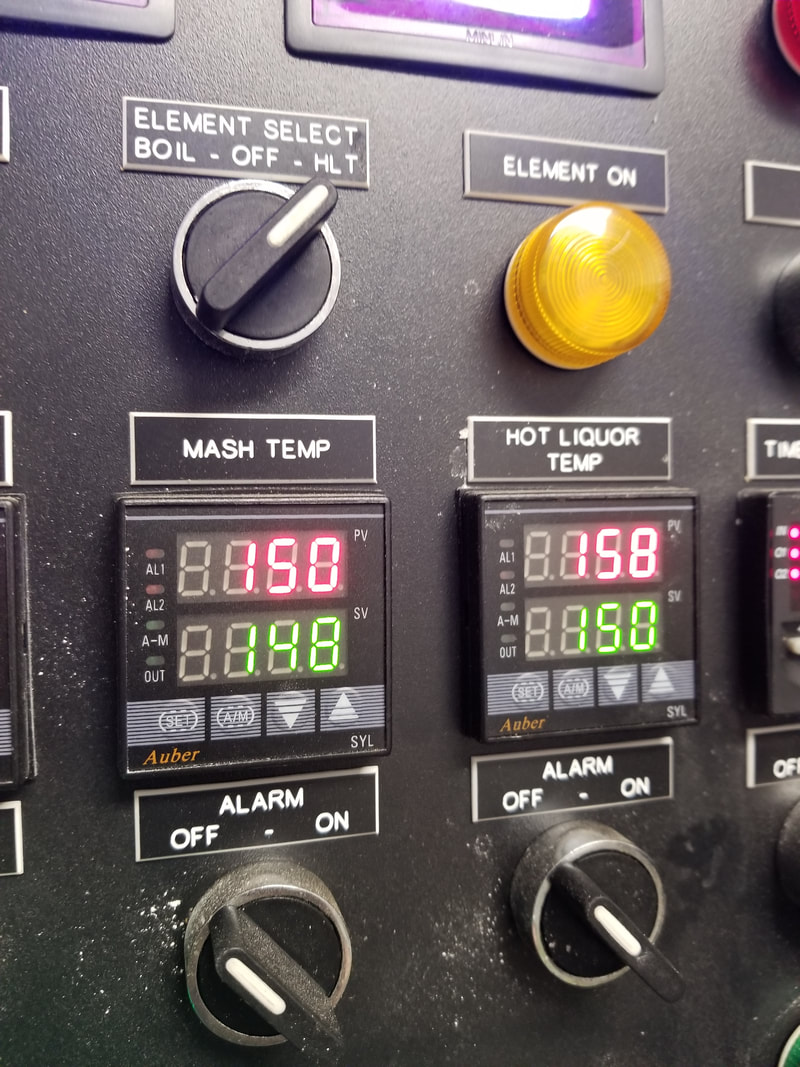

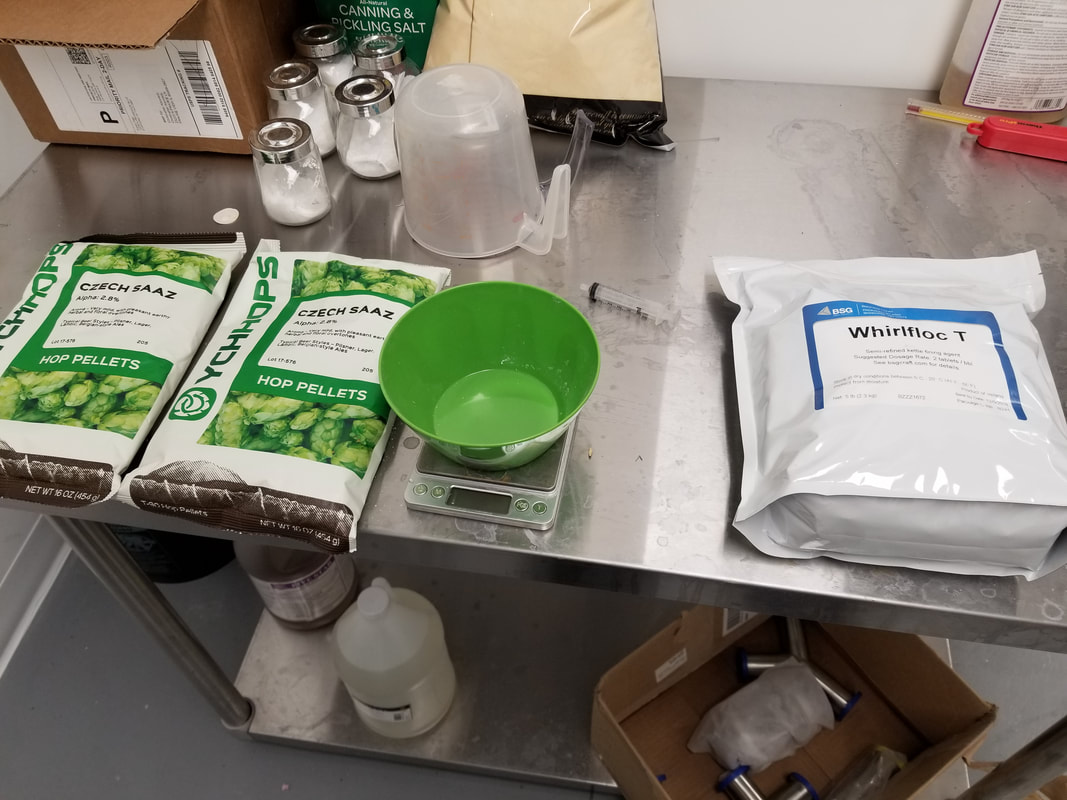

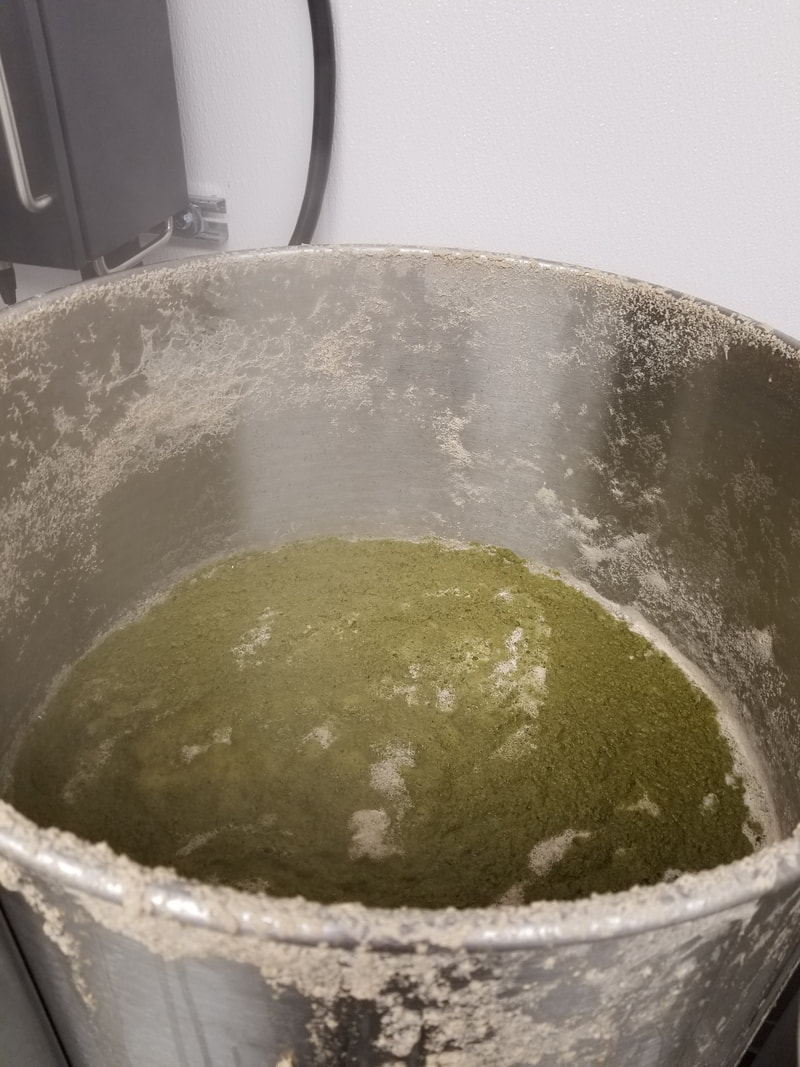

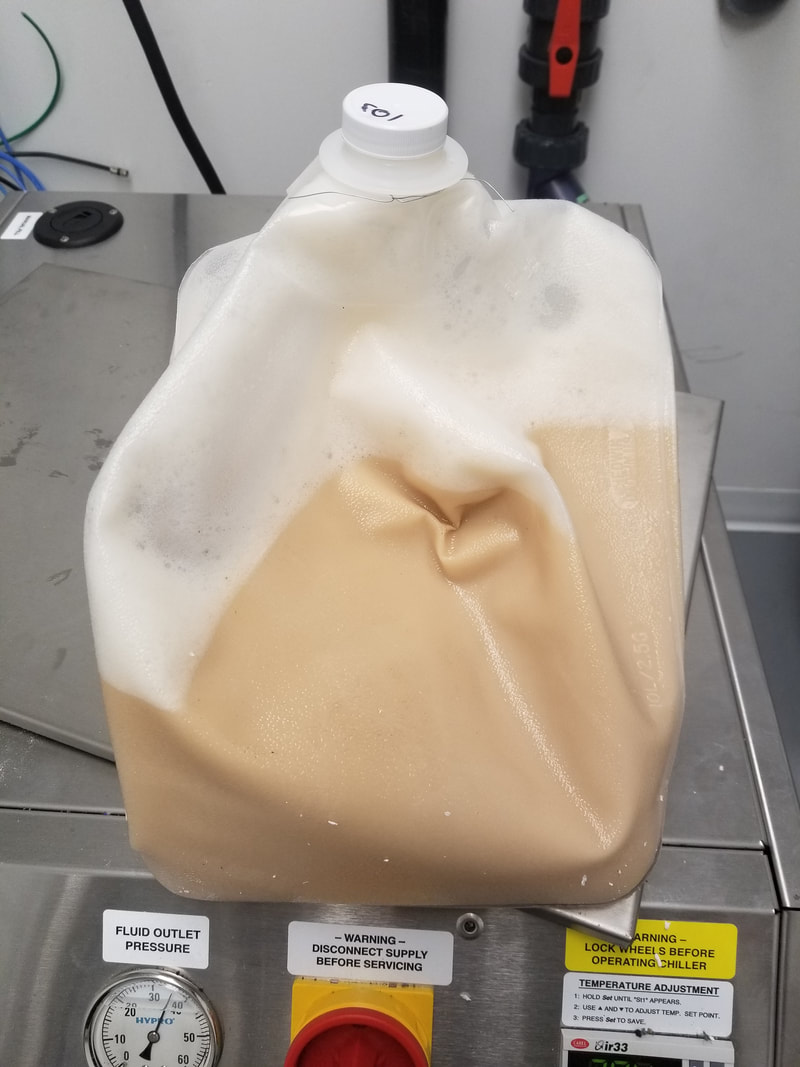

Brewing Days are Here Again!1/12/2019 When we decided to switch from home-brewers to commercial brewers, we had to take a little hiatus from brewing beer to get the business up and running so we have been frothing at the mouth to get back at it for about the last 6 months. In typical feast or famine mode, we went from no brewing, to brewing eight batches of four different beers this last week. Here are some pics from a typical brew day for us: First, we fill the HLT with about 105 gallons of water and get that heating to about 160 degrees. That takes a while so we do some prep work like milling grain. Each recipe is different, but each batch averages about 150 pounds of grain. Once we have the HLT at the temperature we want, we move about half the water over to the mash tun and stir in all the milled grain. Once all the grain is in, we use a recirculating system that draws water from under the grain, runs it through a coil in the HLT that remains heated at the proper temperature, and then back on top of the grain bed. Doing this at specific temperatures, soaks sugar off of the grain and turn our water into wort. After the mash, we fly sparge, which is the process of moving the wort from the mash tun to the boil kettle. This is the mash tun after it has been emptied of wort. The spent grain now has to be shoveled out and disposed of. We are looking for any farmers who want this spent grain as feed. Its free and we hate throwing it away! While we are waiting for the wort to boil, we prepare the hops and other additions. Depending on the recipe, different hops are added at different points in the boil. The Whirlfloc you see on the right is added with 15 minutes left in the boil to help with beer clarity. A rare sighting of our brewers, Chris and Chris. As the wort nears boil temperature, a film forms on top of the wort called the hot break. We skim it off as it helps with beer clarity and stability down the road. Boiling wort. It might not look very appealing in this state, but in about a month you guys are going to be loving it! While the wort is boiling, we have to sanitize our fermenter in preparation for the wort. We use a non-foaming, iodine based sanitizer in this situation and run a loop of it through a clean-in-place (CIP) spray ball at the top of the fermenter. By running the loop through a pump, we generate enough force to make sure all of the tank gets sanitized. If you noticed the buckets of grain in the foreground, those are waiting for our second batch of the day. Every day we brew, we brew twice in order to fill the fermenters. It makes for a long, but fun, day. Once the boil is done, it is time to move the wort into the fermenter. If you can follow the picture, the hose goes from the boil kettle to a pump. From the pump it goes through a heat exchanger (the square thing with blue hoses coming out of it) that takes the wort from 212 degrees down to about 60 degrees almost instantaneously, and then into the fermenter. On this particular day, we were brewing Prairie View Premium Lager and needed to get the wort down to about 50 degrees before pitching the yeast. Once the yeast are pitched, they begin eating the sugar in the wort, turning it into CO2 and alcohol. After about 12 hours of brewing, you'd think the day would be done, but there is a lot of cleaning to be done when the brew day ends. After an hour or two, the brewery is clean and ready for the next brew day.

Construction Wrap Up12/29/2018 Hello All, We hope everyone had a wonderful holiday filled with family, friends, and good beer! We are thrilled to announce that all the construction and installation of equipment is completely finished. The building inspectors and the state liquor commission were both in yesterday and it looks like the Health Department will be here this coming Wednesday. All that is left to do is wait for the official all clear! Barring truly unusual circumstances, it looks like we will be open in time for Superbowl Sunday, February 3rd. Here are some pictures of what we've been up to the last month: Kegs ArriveInstalling the BrewhouseThe Brewhouse. The black barrel on the far right is a holding tank for our reverse osmosis system. The water we use to make our beer is as pure as we can possibly make it, ensuring consistant results for you guys. The kettle on the right is called the Hot Liquor Tank (HLT). That is where we heat the water for the brewing process. The middle tank is the mash tun. That is where we put the milled grain and then soak it in the hot water to create wort (fancy brewer's term for sugar water). The final tank on the left is the boil kettle. That is where we boil the wort and add hops for flavor. From the boil kettle, the wort goes in the fermenters where yeast is added and the wort becomes beer! Fermenters

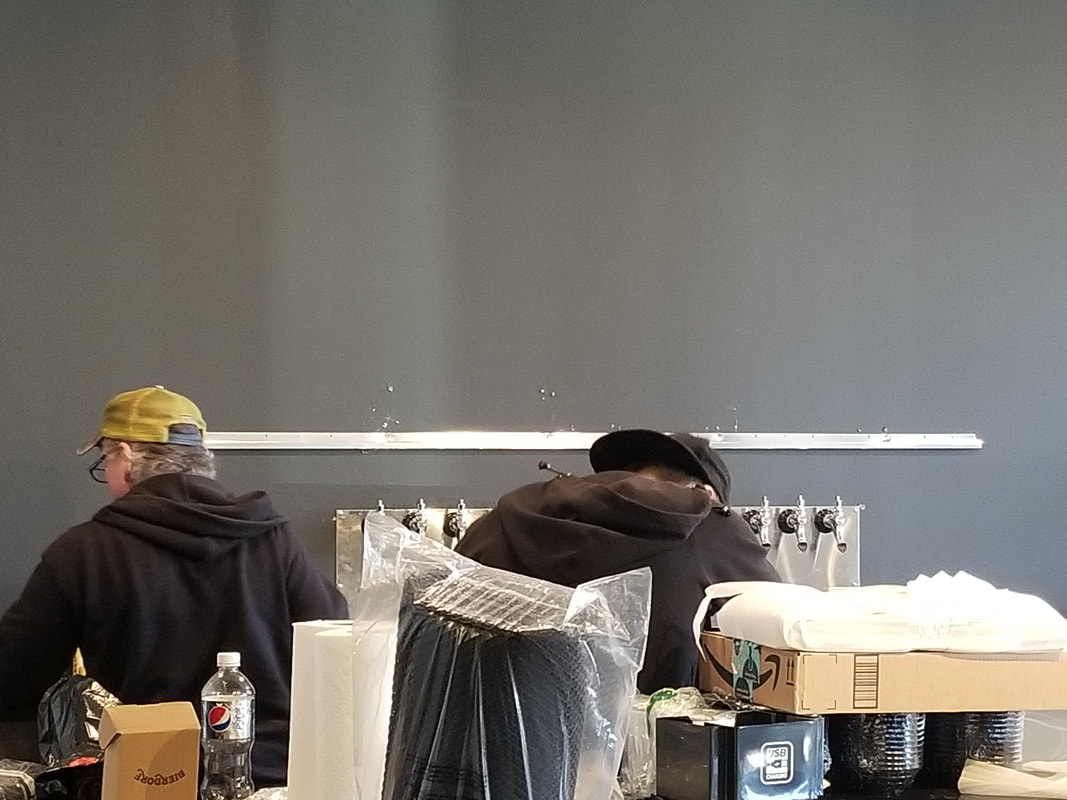

Uncrating the beauties! Ceilings, large glass windows, walls--thankfully these guys knew what they were doing. Not sure how I thought I was going to place these on my own. Last step is adding the glycol piping to the tanks. This allows us to control fermentation temperatures which is quite important for making great tasting beer. Fermenter Row. We have four 5 Barrel Fermenters just waiting to be filled with Black & Gray Brewing Co. beer! TappersDrew from Leader's Beverage installed 12 taps for us. It took a little work, but the taps run right through the cooler wall to the bar so no chance for the beer to get warm. Leader's Beverage will also being cleaning our lines on a regular basis to make sure our beers do not pick up any off-flavors DecorHanging Teresa's mirror over the tappers. The picture doesn't do it justice, it looks awesome! Okay, so December isn't the best time for rolling up the garage door, but we had to try it out. Looking forward to spring when we can have her open all the time and everyone can enjoy the weather. Anyone who knows Chris, knows he can't draw a stick figure or tell you what color we should paint a wall , but when he saw a tatted up Audrey Hepburn and Johnny Cash, he knew right where they belonged. Black & Gray Brewing Co. at night. We wanted to take a moment and truly thank all of you who have followed us on this journey. We can't wait to meet you all and serve you up some top-notch craft beer right in downtown East Dundee. Remember to pencil in February 3rd as our opening day and watch for the official announcement.

January is going to be a very busy month for us. Chris will be brewing a lot of beer and Teresa has hired a great staff who will be training to provide you guys outstanding service. Thanks again for all of your support! Construction Update III11/23/2018 The Taproom has a Bar! Since our last update, a lot has been accomplished! The work being done might not be as dramatic as a new wall going up, or ceilings being completed (and hence, a little harder to document with my poor camera skills), but the guys have been rocking out the work and we are getting very close to wrapping this phase up, and moving onto the next phase: making beer! Here are some recent pictures: Lights in the front of the house are in. Very Important Stuff Here! CO2 installed with Lines Run to the Cooler so We Can Pour You Some Beer! Barring any further hiccups, construction should wrap up around the first week of December. Then we have some inspections to get through, both for the local building department as well as the State Liquor Control Commission. As long as those go well, we should be making beer by middle of December with an anticipated opening date of mid to late January. Next Update Should Have Some Pictures that Look Like This:

|

Proudly powered by Weebly

RSS Feed

RSS Feed